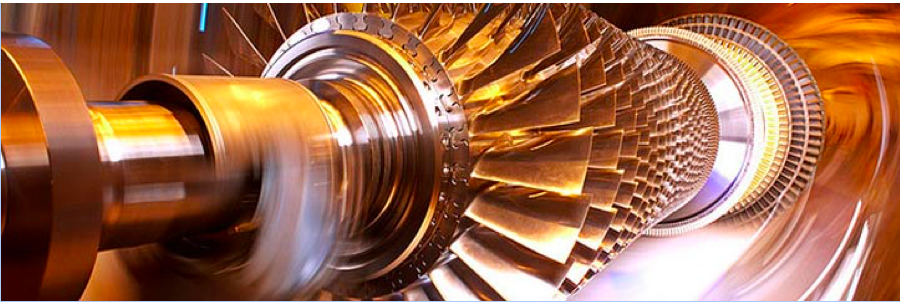

Industrial Gas Turbines

Drive for ever greater efficiency and service life within the Industrial Gas Turbine (IGT) sector has driven designers to incorporate ever greater use of complex radial and local machined features. These in turn require that for an integrated machining solution, a supplier must present both 3/5 axis grinding capability and an ability to machine local features in a manner that embraces the latest control and accuracy that Electro Discharge Machining - EDM machining can offer.

OTM has invested in the latest 5 axis grinding technology with integrated tool changing to allow a mix of features to be machined within a single component machining cycle. Grinding hardware that incorporates both continual dressing and an automated tool changer allows for rapid bulk material removal to be integrated with finer detail completion machining within an optimised machining cycle time.

The later application of EDM hardware that integrated both linear motor for significantly greater machining speed, which in turn improves feature flushing and thus yields greater dimensional stability has also been integrated by application of component pre-probing that will allow for features to be individually matched to a component during its machining cycle, all within a repeatable swift manner.

Finally, our investment into the latest fast hold drilling technology allows us to produce both linear and complex shaped holes within an aerofoil and platform of a gas turbine part.

Throughout our component development process, we perform rigorous first article inspection methods and procedures. Parts are measured with highly accurate CMM’s, optical comparators and dedicated hard gages, with all CMM programmes being verified against a known datum or a comparative CMM programme. After dimensional accuracy has been accepted, metallurgical examination is conducted per customer’s specifications. Upon acceptance of the metallurgical evaluation process parameters are frozen to assure future part integrity and quality.

Contact us for more information regarding our machining of complex components for IGT. We look forward to engineering and proposing solutions for your challenging manufacturing needs